The Problem Every Logistics Manager Knows (and Hates)

Imagine this scene, repeated every day in thousands of warehouses across Europe:

9:00 AM. There are already three trucks in a queue in the yard waiting to load. The first driver is nervous because he’s an hour behind schedule. The second has called three times asking how much longer he has to wait. The third is seriously considering leaving and refusing any future loads from your company.

Meanwhile, your warehouse manager is desperately trying to coordinate everything by memory and with a few notes on a scrap of paper, while the phone rings incessantly with other hauliers asking, "What time should I come?"

The result? Total chaos, operational inefficiency, dissatisfied carriers, wasted hours, and rising costs.

What if we told you there’s a simple way to transform this daily nightmare into a smooth, organized operation?

How Much are Warehouse Queues Costing You?

Before discussing the solution, let’s look at the hard facts. This problem isn't just "a bit of confusion": it is silently eroding your competitiveness and profits.

Direct Costs (The Obvious Ones)

Every time a truck sits idle in your yard waiting:

- You indirectly pay for the carrier’s downtime, which will eventually be recharged to you in some form.

- You block warehouse staff capacity, which could be better utilized elsewhere.

- You slow down the entire operational flow because everything depends on loading/unloading.

- You risk errors when working under pressure to catch up on delays.

European logistics studies highlight that 23% of total transport time is spent in unplanned waiting at distribution centers and warehouses. This represents a massive inefficiency that burdens the entire supply chain.

Hidden Costs (The Ones That Hurt Most)

But the worst damage is often what you don’t see immediately:

- Reputation damage: Hauliers talk. If your warehouse is "the place where you always waste time," they will start avoiding you or quoting higher prices to compensate.

- Loss of flexibility: You cannot accept urgent loads because you have no clear way to organize the yard flow.

- Staff stress: Your warehouse team is constantly working under pressure, leading to low morale.

- Lack of optimization: You have no data to work with to improve your processes.

Even if you only have one loading bay, disorganization costs you much more than you think.

Professional Yard Management: You Don’t Need an Expensive YMS

When it comes to organizing loading and unloading yards, many immediately think of enterprise Yard Management Systems (YMS)—complex, expensive software costing tens of thousands of euros, with months of implementation and consultants explaining features you’ll never use.

The good news? You don't need all that.

For most companies—even those with significant volumes—you need a solution that is:

- ✅ Simple to use from day one.

- ✅ Visual and intuitive (not incomprehensible spreadsheets).

- ✅ Integrated with the rest of your logistics management.

- ✅ Affordable even for SMEs.

- ✅ Scalable as you grow.

And that is exactly what Truckscanner’s warehouse yard management does (internally we call it "Dock Scheduler," but you can simply think of it as your intelligent dock calendar).

How Yard Management Works on Truckscanner

Forget spreadsheets, sticky notes, and endless phone calls. Here is how you can organize loading and unloading operations like a pro.

Step 1 - Configure Your Warehouses and Bays

The first time you access the feature (available in the Premium plan), configuration is incredibly simple:

- Select the warehouse from those already in your profile or add new ones.

- Specify the number of loading bays/areas available (even just one works perfectly).

- Name each bay ("Bay 1", "Area A", "Raw Materials Unloading", etc.).

- Define standard time slots between vehicles (15 min, 30 min, 1 hour – based on your operations).

- Optional: upload a yard map or image to help drivers find their way.

And that’s it. You’re set up in 5 minutes.

Step 2 - View the Dock Calendar

Once configured, you have an intelligent calendar that shows you:

- All bays in side-by-side columns.

- Daily time slots (or weekly if you prefer the extended view).

- Scheduled transport orders placed in their respective slots.

- Real-time availability for new bookings.

No more wondering "What time is that truck arriving?" or "Which bay is free now?". Everything is visible, organized, and under control at a glance.

Step 3 - Manage Orders and Bookings

For every transport order in Truckscanner, you can:

- Assign it to a specific bay using drag-and-drop.

- Define the estimated time of arrival (ETA).

- View all details by clicking on the order (customer, cargo type, special requirements, contacts).

- Send automatic confirmations to the haulier.

When a carrier uses the "Dock Reservation" feature to book a slot themselves, you immediately see the booking in your calendar and can approve or modify it.

Step 4 - Continuously Optimize

As you use the system, you start to see patterns:

- Peak demand times.

- Actual time required for each type of operation.

- Where bottlenecks occur.

- How to better distribute loads throughout the day.

You have the data to improve continuously—no more guessing.

Concrete Benefits for Your Operations

Zero Improvisation

When every truck has a booked slot and you have a clear calendar, you eliminate improvisation entirely. You know exactly what to expect, when, and where.

Automatic Communication

Stop the endless phone calls to confirm times. The carrier books (or you assign), both parties see the same information, and everyone knows the plan. Communication becomes automatic, tracked, and error-proof.

Maximum Dock Efficiency

Your loading areas work at full capacity without gaps or chaotic overlaps. Handle more loads, reduce downtime, and increase productivity.

Better Work Environment for Warehouse Staff

Your team knows exactly when trucks will arrive, how many people are needed, and what equipment to prepare. They can plan their work instead of constantly reacting to emergencies.

"I Only Have One Bay, Do I Really Need This?"

This is the question we hear most often. The answer is: YES, especially if you have only one bay!

With a single loading/unloading area, organization is even more critical. There is no margin for error. If two trucks show up at once, one must wait. Yard management allows you to evenly distribute arrivals and avoid overlaps that cause queues and tension.

Comparison: Before and After Digital Organization

BEFORE (Traditional Management)

- 08:30 - 2 trucks arrive at once; one has to wait.

- 09:15 - A third carrier calls: "What time should I come?" - "Not sure, maybe around 11?".

- 10:30 - The third truck arrives early and gets angry because it has to wait.

- Result: 12 trucks handled, 8 hours of cumulative waiting time, 25 phone calls, high stress levels.

AFTER (Organized with Truckscanner)

- 08:00 - Open the calendar: you see 6 confirmed bookings for the morning, spaced every 40 minutes.

- 08:30 - The first truck arrives on time, loads in 30 minutes, and leaves.

- No phone calls: everyone knows their scheduled time.

- Result: 18 trucks handled, zero unplanned waiting, 5 phone calls, a methodical warehouse workflow.

Same facility, same staff, +50% productivity. Just digital organization.

It’s Not Just Software, It’s Operational Control

We are not talking about "another system to learn." We are talking about regaining control over one of the most chaotic parts of your logistics. It’s about seeing order where there was confusion and making informed decisions instead of reacting to emergencies.

Case Study: Manufacturing Company with 3 Bays

Context: 3 loading bays, approx. 25-30 shipments per day.

Before Truckscanner: Daily yard queues (2-3 trucks always waiting), average wait time of 45 minutes, frequent carrier complaints.

After 1 Month: Queues eliminated, average wait time down to 5 minutes, +20% more shipments handled daily without hiring extra staff, 70% reduction in phone calls to the logistics office.

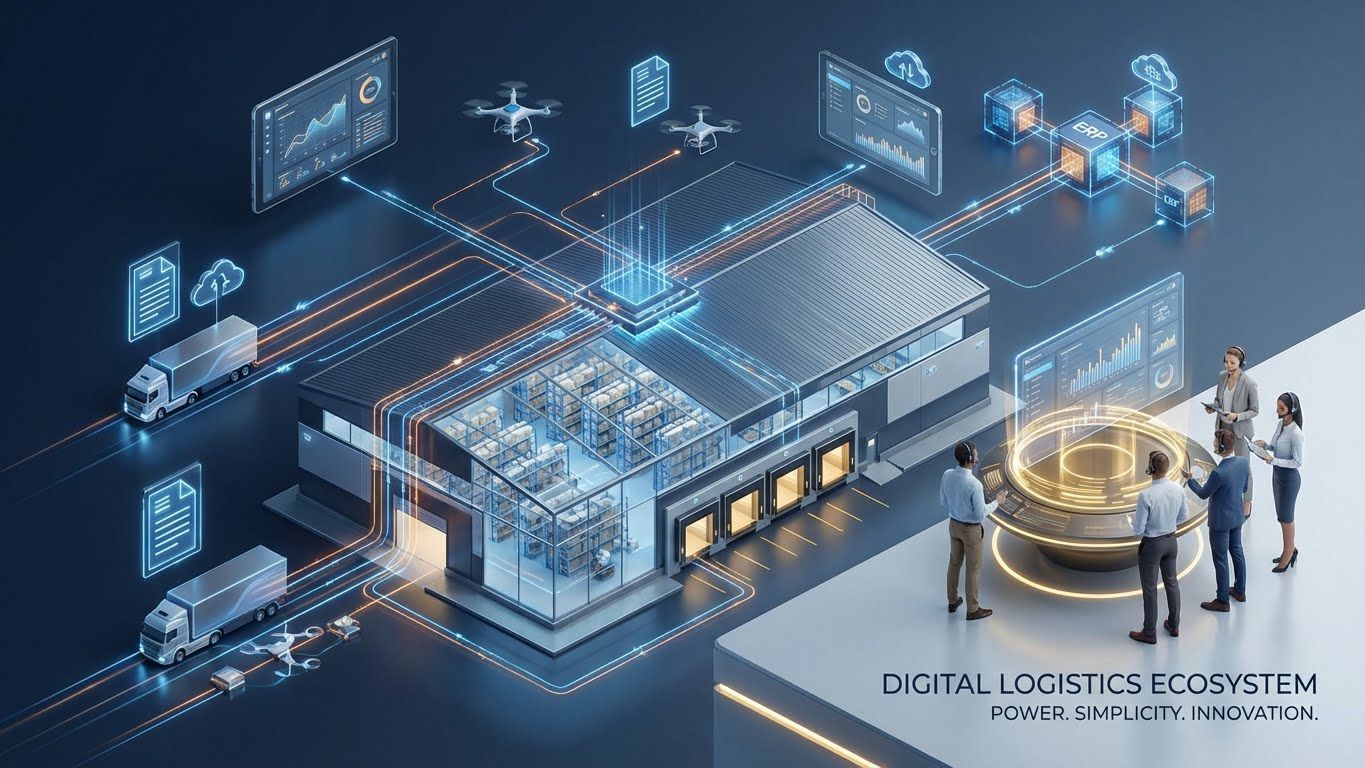

Digitalization Starts at the Foundation

You might have the best ERP in the world, but if your yard is managed by word of mouth and scraps of paper, you have a bottleneck limiting everything else. Organized yard management is the digitalization of the physical touchpoint between your company and your hauliers.

Ready to eliminate the chaos from your yard?

EN

EN

Deutsch

Deutsch  Polski

Polski  Espanol

Espanol  Română

Română  Nederlands

Nederlands  Français

Français  Italiano

Italiano